Expert Solutions for Health & Safety, Quality & Risk Management

-

Workplace Safety Audits & Compliance

-

ACC AEP Auditing & SafePlus Evaluations

- Safety Management Systems for Major Hazard Facilities

-

View more ........

-

Structured Risk Assessments & Mitigation

-

Risk Register development & Review

-

Hazard Identification & Risk Control Strategies

-

ISO Standards & Continuous Improvement

- Internal Auditing & Process Optimisation

- Compliance & Certification Support

- View more ........

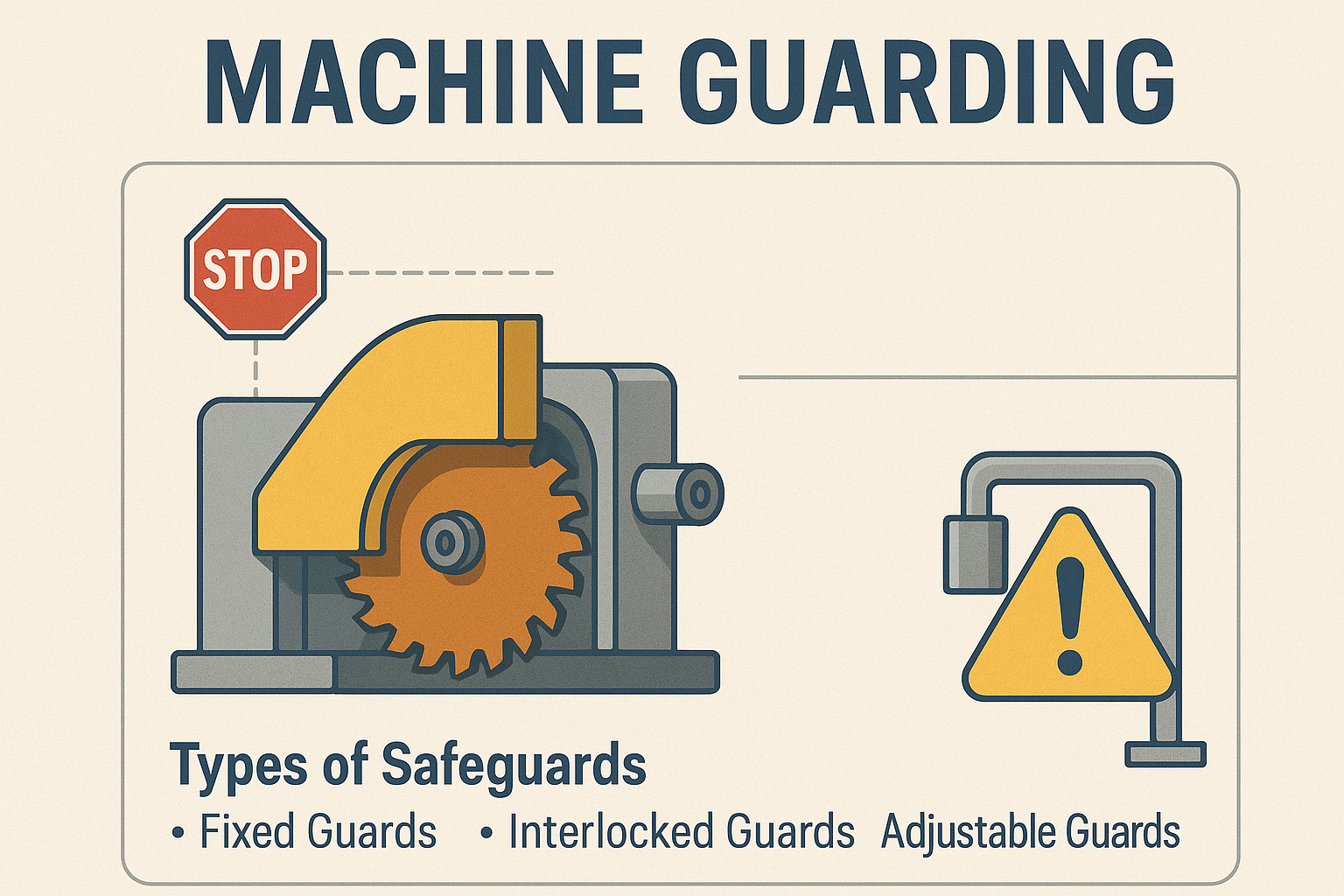

Machine Safety & Equipment Compliance

- Certified Machine Safety Expert Assessments

- Machinery Compliance & Risk Reduction

- Workplace Equipment Safety Evaluations

- View more ........

Internal Auditor Training & Professional Development

- NZOQ-Certified Internal Auditor Training

- Practical Auditing Techniques & Compliance Best Practices

- Professional Development for Quality & Safety Auditors

- View more ........

- AS/NZS-Compliant Electrical Safety Inspections

- Workplace Equipment Testing & Certification

- Detailed Reporting for Compliance Assurance

- View more ........

Based in Manawatū, Serving All of New Zealand

At QHSE, we proudly call Manawatū home, but our expertise knows no boundaries. Whether you're in the Far North, deep in the South, or anywhere in between, we bring our high-quality services to you. No matter the location, we’re ready to support your Health & Safety, Quality & Risk needs across New Zealand.

Industries Served:

With a proven track record across diverse industries, we specialize in delivering customized solutions that address sector-specific challenges and regulatory requirements. Our expertise spans Aviation, Food Manufacturing, Forestry Products, Power, Roading, and Infrastructure, along with a range of other industries. No matter the sector, we bring precision, innovation, and reliability to every project.

Rob Feasey

Rob holds certifications as a Certified Professional Member of NZISM (CertProfNZISM), Chartered Member of IOSH (CMIOSH), Certified Quality Manager (CQM) through NZOQ, and Certified in Risk Management (CertIRM).

As an ACC-authorised AEP Auditor, accredited SafePlus Auditor, and Certified Machine Safety Expert, Rob provides trusted, high-compliance assessments across multiple industries. His approach combines technical precision with practical implementation, ensuring businesses meet regulatory obligations while maintaining operational efficiency.

Known for his clear, solutions-focused approach, Rob collaborates with clients to build robust systems that meet both regulatory requirements and organisational needs.

Get in Touch

Looking for expert guidance in health, safety, risk, or quality management? Whether you need audits, compliance support, or tailored safety solutions, we are here to help.

Reach out today to discuss your needs and find the right solutions for your business.

📞 022 4544445